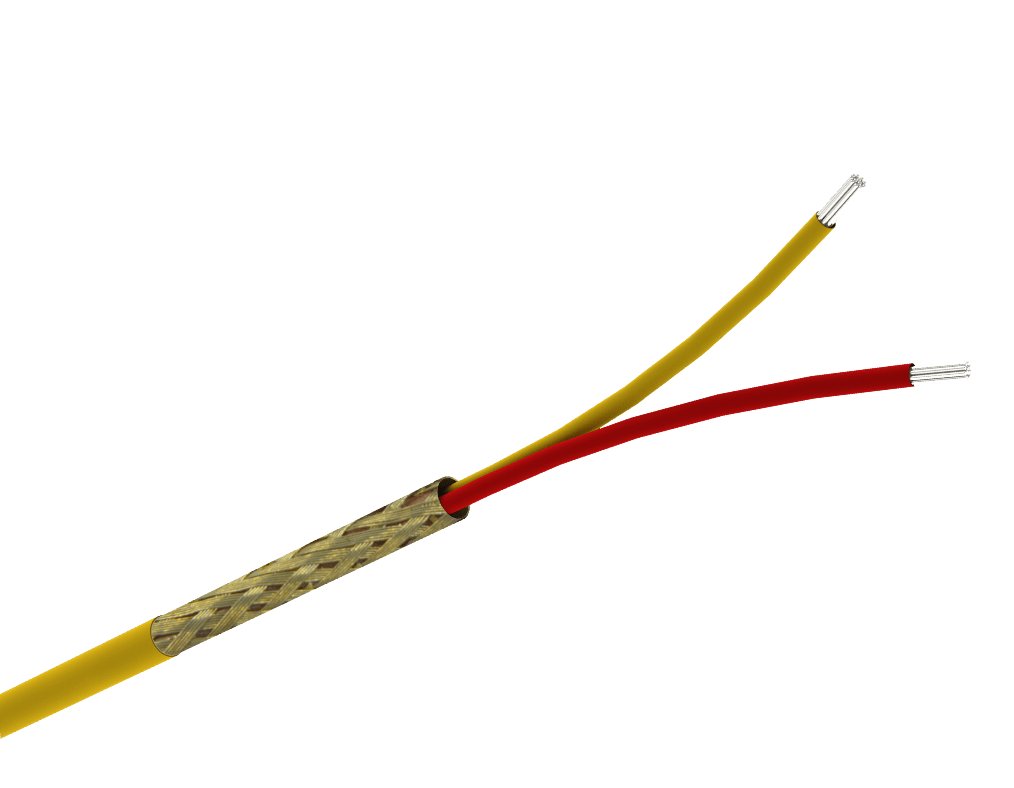

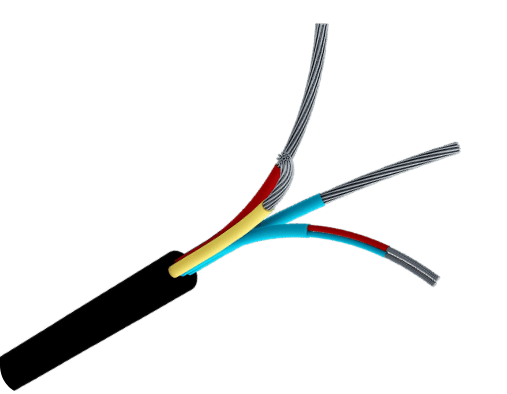

Silicone rubber cables offer prolonged resistance to temperatures up to 200°C and exceptional flexibility. They are widely used in various applications, from temperature sensors in autoclaves to industrial environments where the cable is subjected to continuous static bending.

Key properties:

High-temperature resistance

Excellent flexibility

For higher operating temperatures, we can offer a special silicone rubber compound, providing robust mechanical properties up to 250°C for several thousand hours (with short-term tolerance up to around 300°C).

Silicone rubber insulated cables are generally not recommended for applications exposed to superheated steam (at temperatures above 130°C).

Low-Temperature Flexibility

Cables insulated with silicone rubber maintains good electrical and mechanical properties even at low temperatures, down to -40°C.

Chemical Resistance

Silicone rubber provides good resistance to lubricating oils but is significantly damaged by alkalis, liquid fuels, chlorinated hydrocarbons, esters, ketones, and ethers. It may swell when exposed to naphthenic oils, while aromatic oils, especially at temperatures above 140°C, generally make it unusable.

Flame and Fire Behavior

Standard silicone rubber does not possess inherent flame-retardant properties. However, Siccet offers a special compound (FLAME-RETARDANT SILICONE RUBBER) with additives that increases the LOI (Limiting Oxygen Index) by 25%, allowing the material to crystallize when exposed to flames. This crystallization preserves cable properties long enough for safety measures to be enacted.

For enhanced fire resistance, a special FIRE RESISTANT SILICONE RUBBER compound is used for the conductors insulation, adding a further level of protection.

Tear Resistance

For applications where cables undergo tensile stress, Siccet provides more durable options resorting to tear-resistant silicone made with special compounds.